Technology Summary

BIO WASTE FERTILIZER

At present most recycling methods convert waste to fertilizer via composting, but composting technology produce fertilizer low in active ingredients which cannot satisfy the need for agriculture.

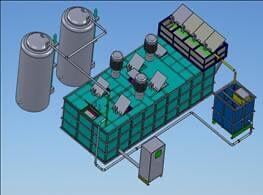

Our company has researched and developed equipment which can produce high quality fertilizer suitable for rapid crop growth suitable for modern intensive agriculture.

As our process converts organic wastes into fertilizer, the product is capable of restoring soil condition which has been depleted of organic material through the overuse of industrial fertilizers and pesticides.

The traditional waste composting fermentation technology cannot reach the effect of organic fertilizers because of fermentation inadequacies, which can result in poor germination and other undesirable side effects.

We developed an organic liquid fertilizer production technology which generates the necessary components for effective farming. We don't use the traditional fermenting methods to produce fertilizer, but rather utilize a two stage process. The first stage uses a microbial food waste malolactic fermentation and a secondary fermentation utilizing amino acids which improve the quality of amino acid in the organic liquid fertilizer.

Because the fertilizer is produced in a liquid form, it is a very convenient for transportation and utilization.

This equipment is ideally suited for animal husbandry operations (Cattle, Poultry or Pig farm), waste collection plant, and meat or seafood processing plants.

The raw materials (waste food, sewage or manure, and other organic plant wastes) is chopped into fine particles

The first fermentation using the microorganisms of lactic acid bacteria

Then the second fermentation process of the lactic acid bacteria

Obtain the mature lactic acid bacteria fermentation liquid(Refining)

Organic active liquid storage(Input tanks)

BENEFITS

Cultivation of safer delicious and nutritious organic food

Using this organic liquid activate soil, make active land becomes more and more fertile.

Elimination of landfill costs for food scraps

ORGANIC WASTE

Livestock waste: Animal waste, animal bones, carnivorous slag etc.

Agriculture waste

Forestry waste: Bark and forestry saws, etc.

Aquatic waste: Intestine bone, fish scale flakes and waste material such as aquaculture

Food industrial waste:Bean dregs, waste sweets etc.

Food processing waste material: Bread crumbs bread, potato chips etc.

Beverage waste: beer, fruit juice, coffee drinks

LIQUID FERTILIZER

Concentration Liquid fertilizer which can mix up to the ratio 1:100 of water

MACHINE CAPACITY

The sizes available are: 50Kg, 300kg, 500Kg, 1T, 3T, 5T and up to 50T per day

MAIN TECHNOLOGIES

Use the light in aerobic or anaerobic condition synthesis microorganisms can effectively aerobic fermentation in aeration slot mixing tank, in the meantime, anaerobic fermentation in anaerobic reaction slots.

- Using the strengths of this two kinds of fermentation way, can produce liquid fertilizer in short period of time, do not produce junk stench.

- Mixed microorganism surfactant with the crushed organic residues, in the meantime make the fertilizer in the fermentation slots reached activeness active decomposition. Put microbial surfactant into micro population in the microorganism slot which can promote the cultivation of fungus.

Comparison table of similar process

| Compost Type | Volume Reduction Type | Reduce Type | Biogas Fermentation Type | |

| Processing Time | Δ | ◎ | Δ | O |

| Manurial Value | O | Δ | ━ | ━ |

| Feed Value | O | O | ━ | ━ |

| Final Product | Δ | Δ | ━ | ◎ |

| Odorous | Δ | O | Δ | O |

| Classification Difficulty | Δ | Δ | Δ | Δ |

| Handling Efficiency | ◎ | ◎ | ━ | Δ |

| Environmental Problems | O | Δ | Δ | O |

| Equipment Amount | O | O | O | Δ |

| Operating Costs | O | Δ | O | Δ |

◎Excellent O Good Δ Below Average ━ Bad

COMPOST TYPE

This method through fermentation, the food waste is dried by heating thus reducing the moisture content. After drying, residual debris wastes need to be incineration or landfill disposal.

VOLUME REDUCTION TYPE

This method through fermentation, the food waste is dried by heating thus reducing the moisture content. After drying, residual debris wastes need to be incineration or landfill disposal.

REDUCE TYPE

Usually utilizes a fungus to break down the food waste into water and carbon dioxide. However, this process is unable to handle some nitrogen and salts, which remain in the end product. These materials interfere with modern intensive agriculture requirements.

BIOGAS FERMENTATION TYPE

The initial investment is high and low efficiency. Low economic efficiency to enterprises

LIQUID FERTILIZER TYPE

The initial investment and operation cost are not too high but the processing time and high value the final product. It will solve a problem for environmental and no wastes will go to landfill disposal.

CONCLUSION

Through all kinds of tests, we concluded that liquid fertilizer plays a very good effect on plant safety and nutrition. its characteristic are more balanced in three elements, medium weight elements, must trace elements and amino acid etc, and amelioration of soil elements carbon/nitrogen is also high. Liquid fertilizers play a good effect on improving crops disease tolerance and reduce crops pesticide and improve the crops flavors.